There is a global need that all manufacturing industries should mark products and parts for traceability. This requirement has dramatically popularized the laser marking process. This is a revolutionary technology applicable to a wide range of industries. The marking process can be used for engraving, etching, annealing, and forming, among others. Industries involved in laser marking technology include the automotive, medical, and aerospace industries.

Choosing a suitable laser marking equipment for that purpose is the greatest challenge for many. Every type of laser marker machine has unique features for specific materials and surfaces. This is why we have created this list of the different types of laser marking machines.

What is Laser Marking

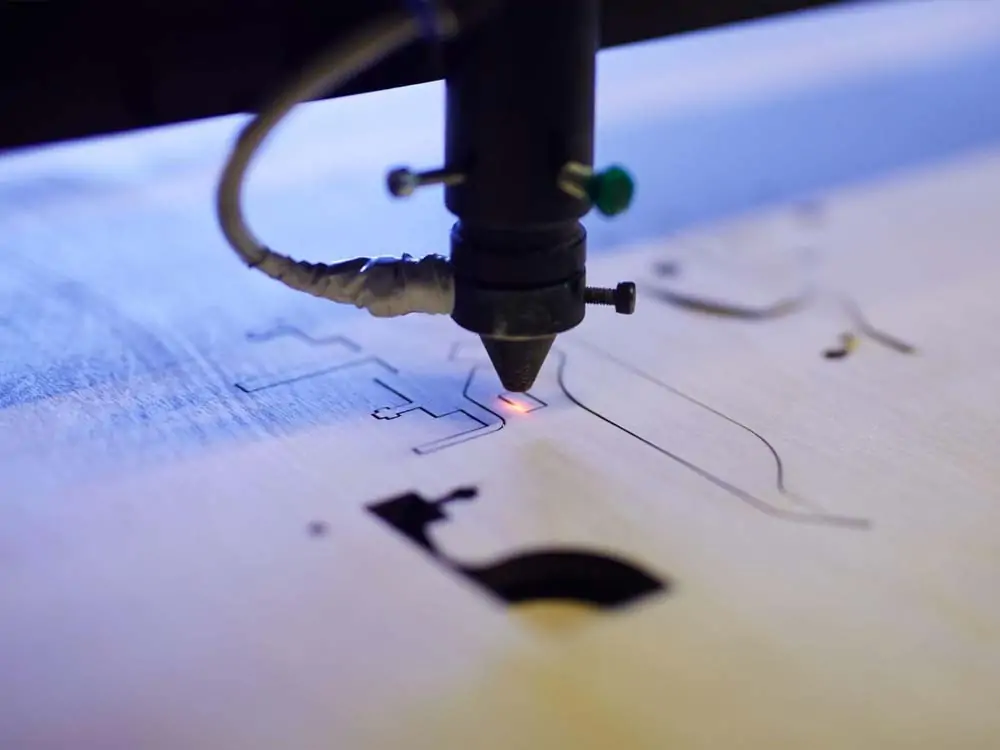

Laser marking is marking a material surface permanently using a focused light beam. Different types of machines can perform the task of laser marking. These machines include:

- CO2 Laser Marking Machines

- Fiber Laser Marking Machines

- MOPA Fiber Laser Marking Machines

- Green Laser Marking Machines

- UV Laser Marking Machines

There are three common types of laser marking techniques, which are:

- Laser engraving that cuts deep into the material to create permanent marks. Laser-engraved markings can withstand abrasion,

- Laser etching that creates high-contrast marks on the material surface.

- Laser annealing is a marking process that creates marks under the material surface. Laser annealing does not affect the base metal or the protective coating of the material.

You can laser mark several materials. Including steel, stainless steel, aluminum, polymers, wood, and rubber. The laser marking technology applies to products and parts with barcodes, VINs, logos, and alphanumerical serial codes.

Types of Laser Marking Machines

There are several types of laser marking machines available in the market. Each of them has its own unique characteristics and applications. Here are some commonly used types:

CO2 Laser Marking Machine

The CO2 laser is among the oldest laser marking techniques on the market. The technique has been in the marking business since the 1960s. Until now, it is still one of the most reliable marking methods. CO2 laser marking machines use a carbon dioxide gas laser source to generate a laser beam. They are mainly used to mark non-metallic materials. Examples include wood, acrylic, glass, paper, leather, and fabric.

CO2 lasers are known for producing high-quality engravings and deep marks. It can be applied to projects requiring precision, mass production, and personalization. High levels of precision characterize CO2 laser markers. And it can be used to mark various materials, including wood and plastics.

Every CO2 laser marker features a gas-filled glass tube. The tube has mirrors at both ends. One mirror is fully reflective, while the other allows light to pass through. When electricity is passed through the glass tube, the two mirrors guide the light as a laser beam to the material.

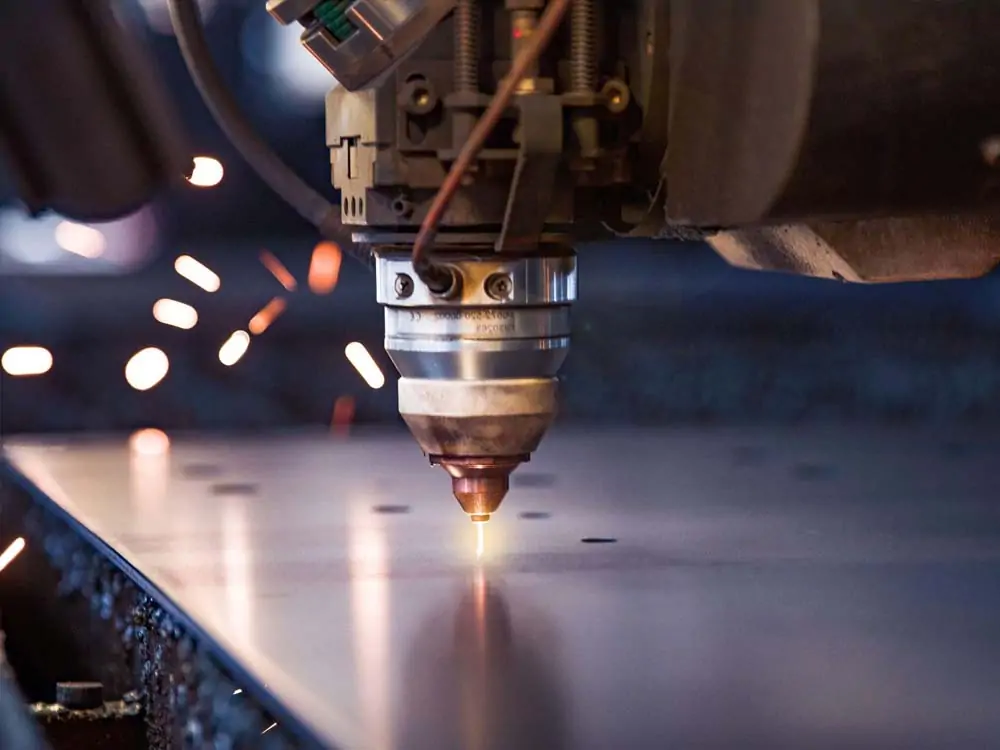

Fiber Laser Marking Machine

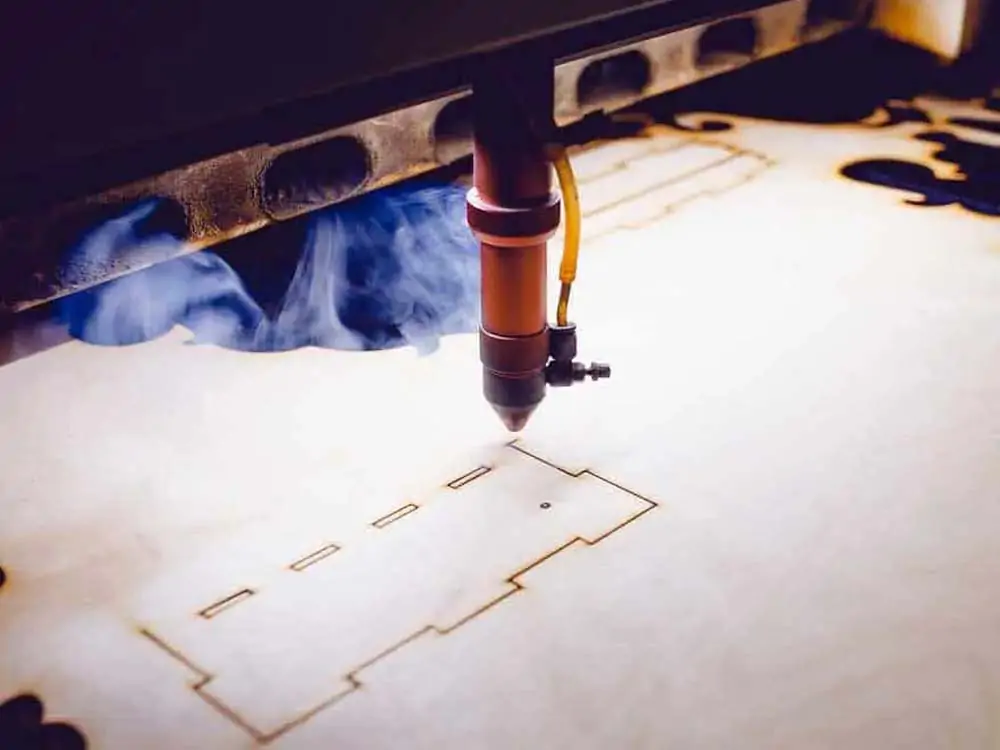

Fiber laser marking machines are highly specialized tools. This marking laser machine uses a fiber laser source to generate a laser beam. A laser fiber marking machine can create high-quality, durable laser cuts on various materials. Including the toughest ones on the market. Includes metals, plastics, ceramics, and some organic materials. Fiber lasers provide high beam quality and reliability and can produce precise and permanent marks.

The laser fiber marking machines use fiber optic cables made of bundles of fibers to transmit light waves to the workpiece. This property differentiates the fiber laser technique from the other laser mark techniques. The difference is also visible in the final product. Fiber laser marking machines produce clean cuts and tight bonds between materials.

MOPA Laser Marking Machine

MOPA (Master Oscillator Power Amplifier) uses a pulsed fiber laser with MOPA configuration. It is a variant of fiber laser marking machine. But the MOPA laser marking machine has additional pulse duration and frequency flexibility. MOPA lasers are known for producing high quality marks on a wide variety of materials. Including metals, plastics, ceramics, etc.

MOPA laser marking machines are versatile and flexible. Therefore it is suitable for a wide range of marking applications. The ability to control pulse duration and frequency allows for greater control over the marking process. So it can achieve various effects and improve marking quality.

Green Laser Marking Machine

Green laser marking machines use a solid-state laser source that emits green light. They mainly label materials with high absorption in the green spectrum. Examples include copper, gold, and certain ceramics. Green lasers provide excellent beam quality, ideal for fine marking and engraving applications.

Green laser markers are the perfect machines for highly reflective materials. While other laser markers produce laser beams that the naked eye cannot see, green lasers have visible green wavelengths. The green laser markers have narrower beam diameters. It enabled them to achieve high precision in micro marking. This laser marking technology is widely used in the electronics and semiconductor industries.

UV Laser Marking Machine

The UV laser marking machine utilizes a UV laser source to generate a laser beam. They often mark sensitive materials such as plastics, glass, and metals. UV lasers provide an exact beam with a minimal heat-affected zone. It is, therefore, suitable for marking applications requiring high precision. On the other hand, a laser UV marking machine is versatile. With a UV laser machine, you can mark any and every material.

Advantages of Laser Marking

Laser marking is a versatile and widely used technology that offers several advantages across various industries. Here are some of the key advantages of laser marking:

Permanent And High-Quality Markings

Laser marking creates exact and permanent markings on a wide range of materials. It achieves by altering the material’s surface properties without causing any damage. The laser marks are clear, legible, and resistant to wear, chemicals, and environmental factors.

Non-Contact And Non-Destructive

Laser marking is a non-contact process. This means no physical contact exists between the laser system and the material being marked. This eliminates the risk of damage to delicate or sensitive components. Additionally, it allows marking on uneven or irregular surfaces. And it doesn’t alter the material’s structural integrity.

Wide Range of Materials

Laser marking can be applied to various materials. Including metals, plastics, ceramics, glass, rubber, and wood. It offers excellent compatibility with various materials. So it is suitable for various industries such as automotive, electronics, medical devices, aerospace, and packaging.

High Precision And Complexity

Laser marking systems offer exceptional precision, It can create intricate and complex designs, logos, serial numbers, barcodes, and other markings. Laser marking allows extremely precise control of the laser beam, resulting in fine detail and high-resolution marks.

Speed And Efficiency

Laser marking is a rapid process. It can mark multiple parts simultaneously, making it highly efficient for large-scale production lines.

Integration With Automation

Laser marking systems can be easily integrated into automated production lines or computer-controlled processes. They can be programmed to mark parts in sequence, read data from a database, or communicate with other manufacturing equipment. The result is a seamless integration and efficient workflow.

Conclusion

As an efficient and accurate marking equipment, laser marker machine has become an indispensable and important tool in modern industrial production and technological development. With different types of laser marking machines, we can achieve clear, long-lasting marks and engravings on a variety of materials.

There are many types of laser marking machines with different functions. According to different needs and application scenarios, it is very important to choose the appropriate laser marking equipment. When choosing and using a marking laser machine, we should fully understand its principle, characteristics and scope of application.

In short, as an outstanding representative of modern technology, laser marking equipment have brought revolutionary changes and innovations to all walks of life. By understanding different types of laser marking machines, we can better understand their application fields and advantages. Thus bringing more opportunities and possibilities to our work and life. It is believed that with the continuous development of technology, marking laser machines will continue to promote the progress and development of our society.