Laser engraving is the etching of designs, logos, or text onto various materials using a high-powered laser beam. This technology has revolutionized the way businesses personalize and produce products. It has become an essential tool for many modern businesses. Because it delivers unrivaled precision, efficiency, and versatility.

Today, laser engravers are used in many industries. Including manufacturing, healthcare, arts, and education. Understanding the technology behind laser engraving is critical for businesses looking to incorporate it into their production processes. So today, we introduce you to how the laser machine works.

How Laser Engraving Works

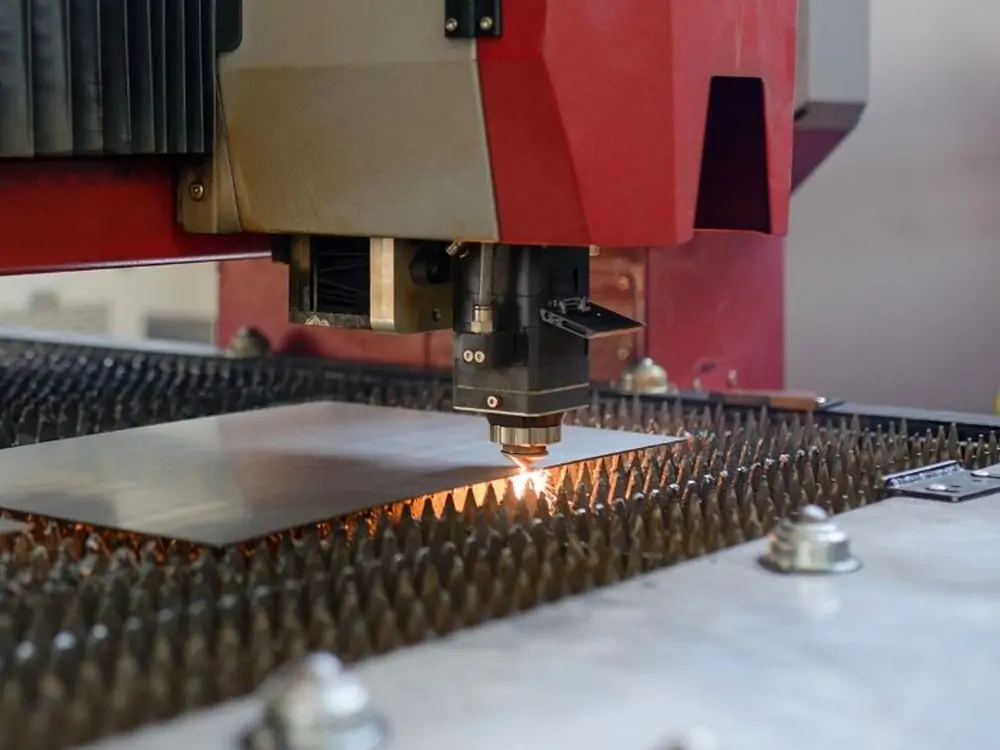

Laser engraving is a process that uses a laser to etch designs or text onto a material. The laser engraver machine works by directing a high-powered laser beam onto the material to be engraved. The laser beam vaporizes the material on the surface, creating a depression that forms the engraved design. A laser engraver machine can be used on various materials. Including metals, plastics, glass, wood, leather, and more.

The precision of laser engraving allows for detailed and intricate designs to be engraved on a material. The laser engraving process can be controlled using specialized software. It allows for customization and high accuracy. The power and speed of the laser can be adjusted depending on the material and the desired depth and complexity of the engraving.

Laser engraving is a fast and efficient process with minimal waste. It has no physical contact with the material, which reduces the risk of damage or distortion. Different types of lasers can be used for laser engraving. Including CO2, fiber, diode, and YAG lasers. Each of them has its advantages and applications. Laser engraved products have a high-quality, professional look. And it can add value and uniqueness to a business or personal project.

What Happens During Laser Engraving

Laser engraving is a popular process of using a laser beam to mark or engrave a material’s surface with high precision. Here is a detailed explanation of what happens during laser engraving.

Preparing the Material

The first step in laser engraving is preparing the material that needs to be engraved. The material’s surface should be clean and free from debris, dust, or oil. This ensures that the laser beam can accurately and effectively engrave the material.

Setting up the Laser Engraving Machine

Once the material is prepared, the laser engraving machine needs to be set up.

The machine’s settings are adjusted based on the type of material, the depth and size of the engraving, and the desired outcome.

Creating the Design

The design or text that must be engraved is created using computer software. It sends instructions to the laser engraving machine. The software allows precise control of the laser beam. It can ensure the design is accurate and high-quality.

Laser Engraving

Once everything is set up, the laser beam is directed at the material, which vaporizes and melts the surface. The laser’s heat causes the material to change color, creating a visible and permanent mark or engraving. The laser beam moves back and forth over the surface, engraving the design in a scanning process.

Cooling Down

After the engraving, the material must be allowed to cool down. This is to avoid any warping or deformation of the material. Cooling can be done naturally or with the help of air or water cooling systems. It depends on the type of material.

Finishing

The final step is removing any debris or dust left behind during engraving. The material can then be coated with a protective layer to prevent damage or scratches.

What Materials Can Be Laser Engraved

Laser engraving is a versatile process used to mark or engrave various materials. Some of the most common materials that are compatible with laser engraving include:

Metals

Many metals can be laser engraved, including stainless steel, brass, copper, titanium, aluminum, etc.

Laser engraving can create precise and intricate designs on metals. It is commonly used in the jewelry, aerospace, and automotive industries.

Plastics

Plastics such as acrylic, polycarbonate, PET, ABS, and PVC are popular materials for laser engraving.

The laser beam can create permanent markings or engravings on the surface of these materials. It is commonly used in signage, name tags, and trophies.

Wood

Wood, including hardwoods and softwoods, can be laser engraved to create intricate designs and patterns.

Laser engraving can create custom designs on wood products such as furniture, picture frames, and signs.

Glass

Laser engraving can etch glass surfaces such as wine glasses, mirrors, and decorative items.

The laser beam can create precise and intricate designs on the surface of the glass, creating a permanent mark.

Leather

Leather can be laser engraved to create custom designs, logos, or lettering. This is commonly used in the fashion industry for belts, wallets, and jackets.

Stone

Laser engraving can etch designs or lettering onto stone surfaces, such as marble, granite, and slate. This is commonly used for custom home decor, gravestones, and memorials.

In general, heat-resistant materials that can withstand the high temperatures and energy of the laser beam can be compatible with laser engraving. But it’s important to note that different materials need different laser settings and parameters. Some may must more precautions or considerations.

Types of Lasers Used in Engraving

Different lasers are used in engraving, including CO2, fiber laser engraving, diode, and YAG. CO2 lasers are the most common laser engraving machine. It is used to engrave wood, plastic, and acrylic materials.

Fiber Laser Engraving and Why it is Popular

Fiber laser engraving is used for engraving on metal surfaces. While diode lasers are used for engraving on materials like paper and cardboard. YAG lasers engrave materials like glass, crystal, and metal.

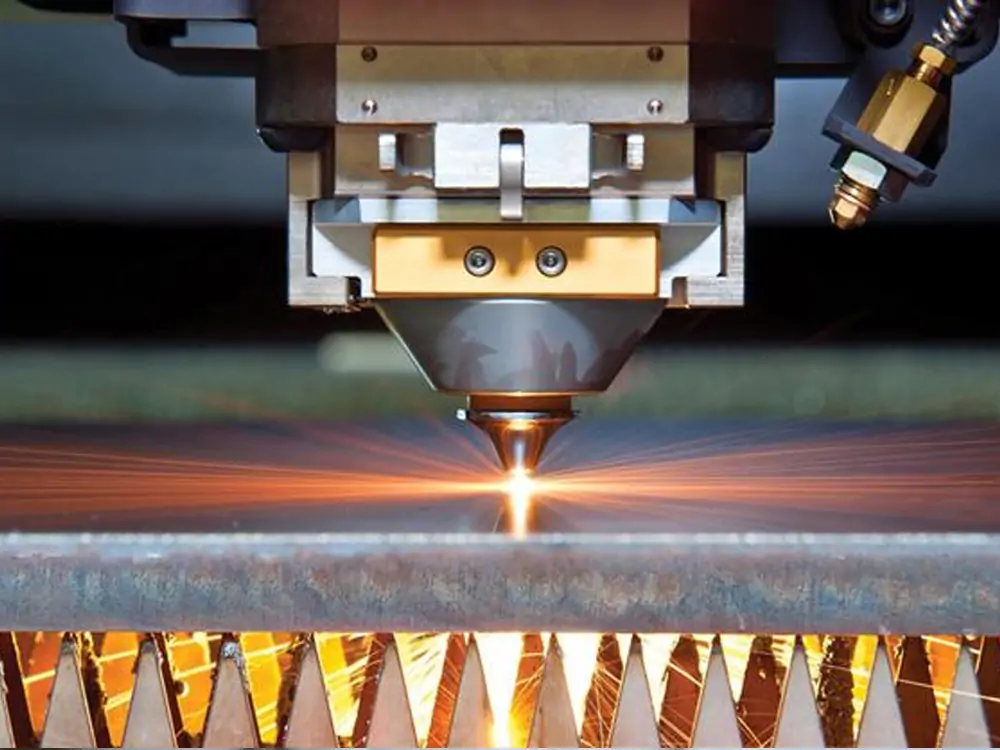

Fiber laser engraving is a type of laser engraving. It uses a fiber laser beam to create marks or engravings on a material’s surface. The laser beam is generated within an optical fiber, which amplifies and focuses the light. It will result in a highly concentrated and precise beam. This type of laser engraving is ideal for creating detailed and intricate designs on a wide range of materials. Including metals, plastics, and even ceramics.

Fiber laser engraving offers several benefits over other types of engraving methods.

Firstly, fiber laser engraving is incredibly precise. It can create fine details and small text that is impossible with other methods. Additionally, the process is fast. The laser beam can engrave quickly and efficiently. So it can save time and reduce production costs. Fiber laser engraving is also very versatile. It can engrave various materials, including reflective materials like metals.

The Benefits of Laser Engraving

High Precision and Accuracy

Laser engraving machines offer high precision and accuracy. These are critical in producing high-quality products. Laser engraver machines can achieve intricate designs and small text. That would be impossible to achieve with traditional engraving methods.

Speed and Efficiency

Laser engraving is much faster and more efficient than traditional engraving methods. Laser engraving machines can produce products faster than traditional methods. It also can reduce production time and costs.

Versatility in Material Types and Designs

Laser engraver machines can engrave on various materials. Including wood, metal, glass, acrylic, and plastic. This versatility allows businesses to offer their customers a wide range of products. Also, laser engraving machines can engrave intricate and complex designs. This allows businesses to create unique products.

Cost-effectiveness

Laser engraver machines are cost-effective in the long run. Because they reduce production time and costs. Also, they require minimal maintenance, which translates to lower maintenance costs. Laser engraving machines can engrave on various materials. It reduces the need for specialized engraving machines.

Customizability

Laser engraving allows businesses to offer customized products to their customers. It is becoming increasingly important in the modern market. Customization allows businesses to differentiate themselves from their competitors and attract more customers.

Applications of Laser Engraving

Laser engraving is a versatile technology that can be used in various applications. Here are some of the most common uses of laser engraving:

Personalization of Consumer Products

One of the most popular applications of laser engraving is the personalization of consumer products. This can include phone cases, jewelry, and promotional items. Laser engraving allows for high-quality, permanent markings that can be customized to suit the needs of the individual. Various laser engraved products are available in the market. These are undoubtedly the most in-demand products in their segments.

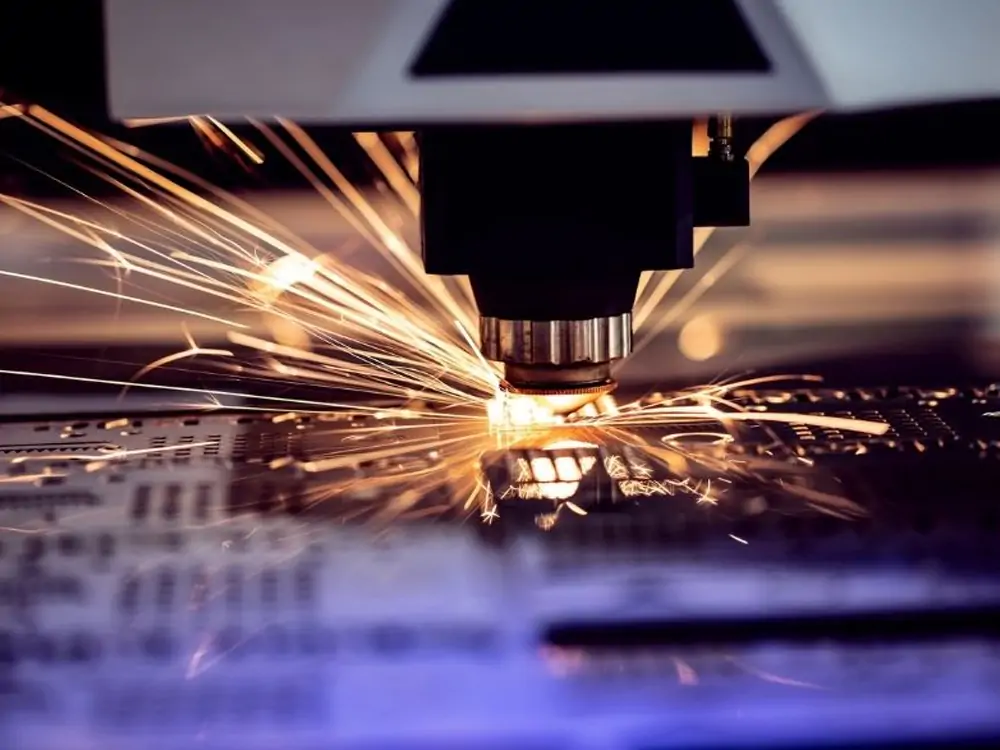

Industrial Applications

Laser engraving is widely used in industrial applications. Such as cutting, marking, and creating laser engraved products. Among the materials, you can use it on are metals, plastics, and ceramics. The precision and speed of laser engraving make it an ideal choice for high-volume production runs.

Medical Applications

Laser engraving is used in various medical applications. Including the marking and engraving of surgical instruments and medical devices. Laser engraving allows for precise and permanent markings that withstand harsh sterilization.

Artistic Applications

Laser engraving is a popular technology for artists and designers who want to create unique and intricate designs on various materials. Laser engraving allows precise and detailed markings customized to suit the artist’s needs.

Educational Applications

Laser engraving is also used in educational settings for teaching purposes. It can be used to create models and prototypes for students to study and to engrave materials such as wood, acrylic, and plastic.

Conclusion

In conclusion, laser engraving is a versatile and precise technology. It can benefit businesses in various industries. From consumer products to industrial applications, laser engraving provides high-quality, cost-effective solutions for all your engraving needs.

With its sustainability benefits and promising future developments, laser engraving is a technology that businesses should consider for their operations.