What is Laser Engraving?

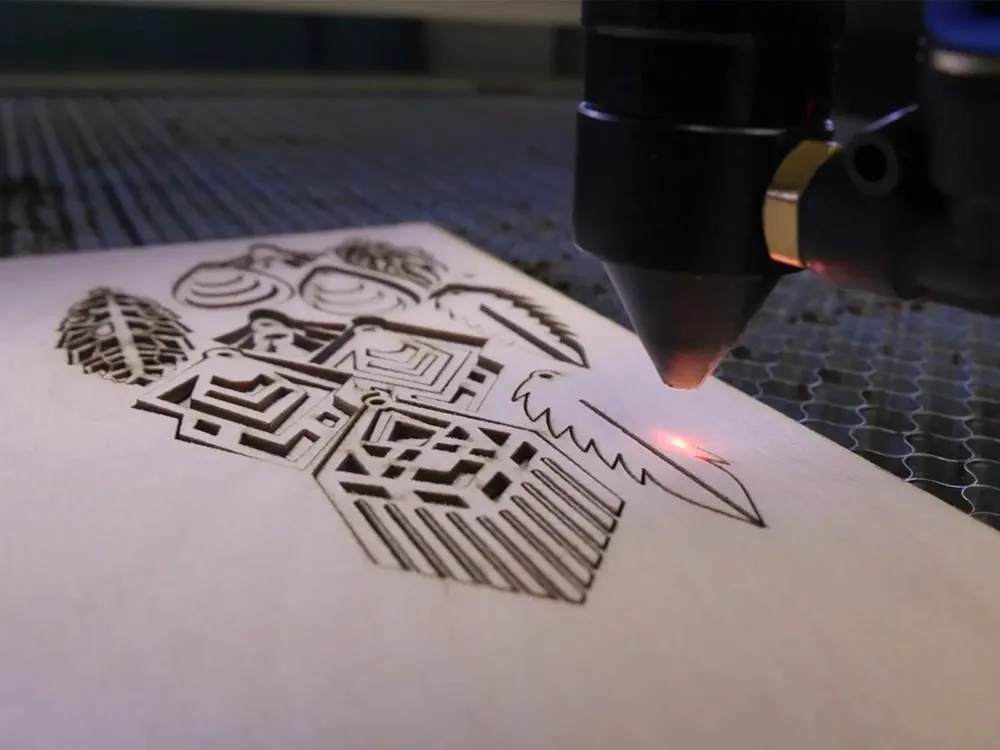

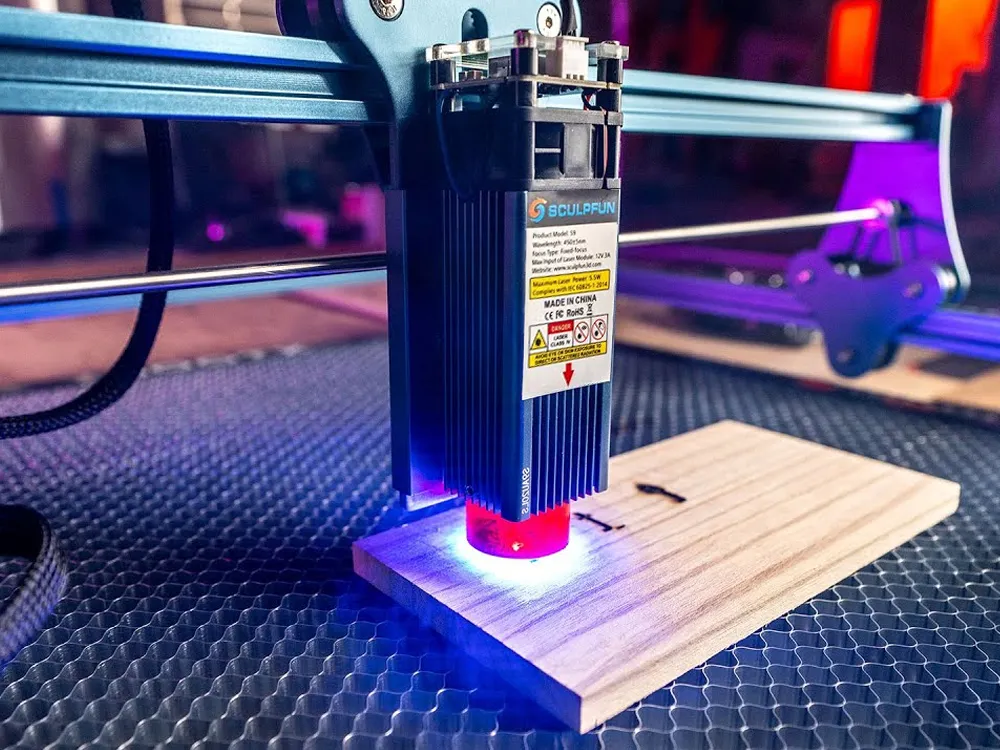

Laser engraving refers to projecting a high-energy laser beam onto the surface of a material. It is a laser processing process that uses the thermal effect generated by the laser to produce a clear pattern on the surface of the material.

Classification of Laser Engraving

Generally speaking, laser engraving processing is divided into the following three types according to the processing effect:

Laser Engraving Line Processing

Using the laser beam, a sharp line effect is produced on the material’s surface.

Laser Engraving and Filling Processing

Using a laser beam, the entire surface layer of the material in a specific area is vaporized. Thereby forming a processing method with a concave effect.

Laser Engraving Hollow Processing

Using a laser beam, all the material in a specific area is vaporized. Thereby forming a processing method with a hollow effect.

What Are Laser Engraving Materials

The process of engraving with a laser is very simple. Just like using a computer and a printer to print on paper, you only need to use various graphics processing software in the Windows environment. Laser engraving can shoot a laser onto almost any material, from woodwork to acrylic.

Wood

Wood is by far the most commonly used laser processing material. Wood is easy to carve. Light-colored woods such as birch, cherry, or maple vaporize well with lasers and are suitable for laser engraving. Each kind of wood has its characteristics. Some are denser, such as hardwood. Larger laser power is required when engraving. We recommend researching the properties of an unfamiliar wood before carving it.

MDF

The surface of the high-density board is covered with thin wood grain. A laser can do the engraving here. However, the color of the engraved pattern is uneven and black and generally needs to be colored. Usually, you can get better results by learning the proper design and using 0.5mm two-color plates for mosaics.

Acrylic

Acrylic is the most common carving material after wood. It comes in various shapes and sizes, is easily carved, and costs less. Since acrylic is a type of plexiglass, it will have a white frosted effect after laser engraving. So the acrylic you engrave must be of high purity. Otherwise, there will be a melting phenomenon after engraving.

Double Color Board

Double-color plate is a kind of engineering plastic specially used for engraving. It is composed of two or more layers of color compounding. Its specification is generally 600*1200mm, and a small amount is 600*900mm. The engraved two-color board is usually used for various signage and name badges.

Glass

Lasers can be used to engrave on glass surfaces. But the carving depth is not deep. The laser can generally form a frosting or shattering effect on the glass surface. But that’s not what we want. So be extra careful when carving.

Laser Engraving Advantages

Compared with traditional engraving methods, laser engraving has obvious advantages:

Wide Range of Engraving

Both technical and non-metallic materials can be engraved. Even brittle and hard materials such as ceramics and quartz can be engraved.

High Speed

Laser engraving is more than 100 times faster than conventional engraving methods. And the most important thing is to be able to guarantee the accuracy of repeated engraving.

High Quality

The product has high resolution and can realize fine engraving. The machining accuracy can reach 0.1mm.

Non-contact Processing

The engraving process is clean and pollution-free. The area affected by oxidation, deformation, and thermal expansion of the engraved material is small.

Less Energy Consumption

The engraving process is simple, and there are few energy conversion links. And it is fine engraving, with less loss of raw materials, which can improve work efficiency.

High Degree in Automation

The combination of laser engraving and automatic control technology can easily realize automatic control.

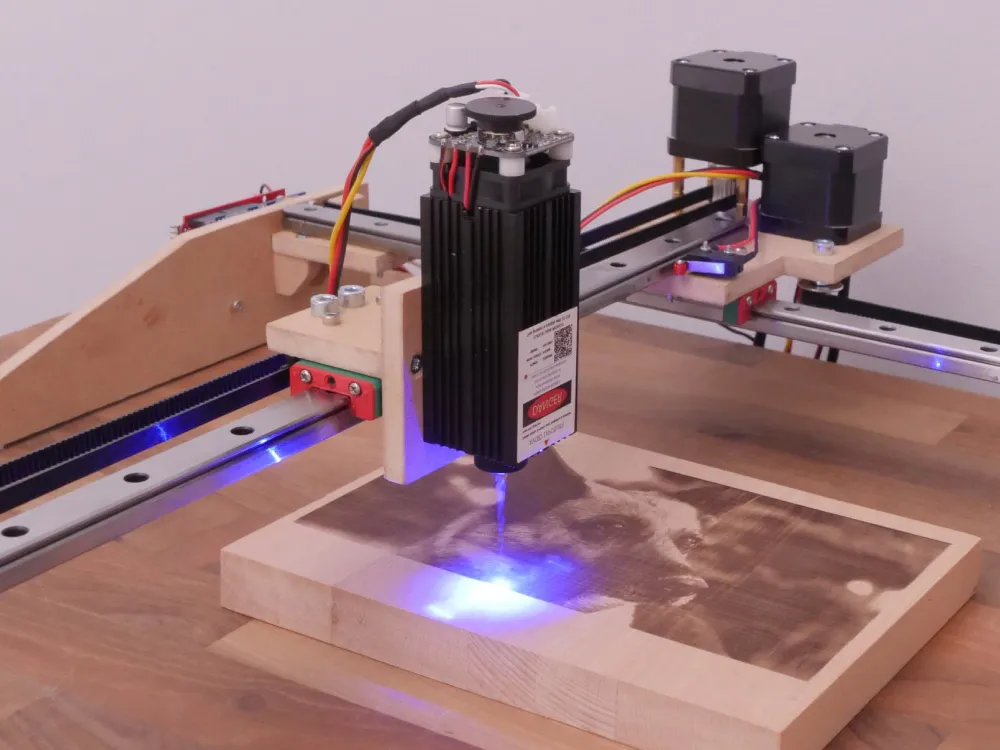

What is a Laser Engraver?

The laser engraver machine generates laser light through a laser. It is transmitted by the emitting mirror and irradiated on the material to be engraved through the focusing mirror. This advanced equipment can improve the engraving efficiency and make the engraved surface smooth and round.

Types of Laser Engraving Machines

Laser engraving machines can be divided into metal and non-metal laser engravers. You can use the following five types of laser engraving machines in the specific production process. The following are their characteristics.

Fiber Laser Engraver

The fiber laser engraving machine uses a high-speed scanning current mirror system to realize the engraving function. It is mainly used for metal engraving. The output beam quality is good, the reliability is high, and the operating life is long. The fiber laser engraver is mainly used in fields requiring high depth, smoothness, and fineness.

Features:

- From the appearance, the overall structure is integrated, easy to carry, and saves production space.

- The beam quality is high, and the resolution can reach 1 micron.

- The fiber life is about 100,000 hours.

- Up to 600 characters per second are more than 3-8 times that of the ordinary laser.

- Low power consumption.

- Stable laser power and high reliability. It can meet the production demand of continuous and stable processing for 24 hours.

CO2 Laser Engraver

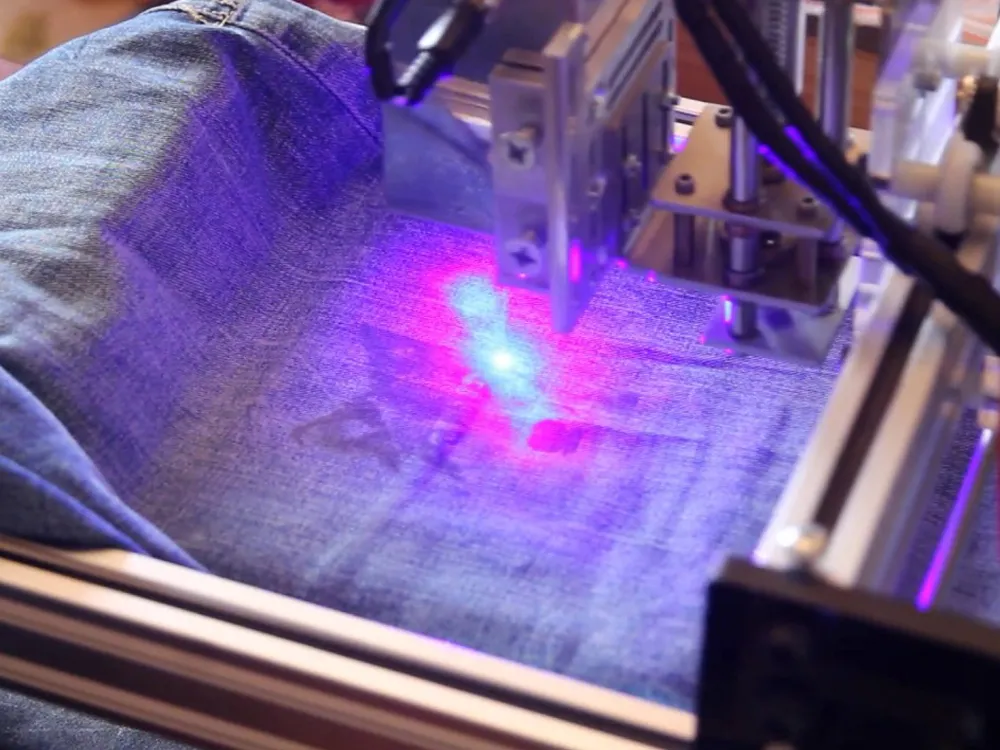

CO2 laser engraving machine is an engraving machine using carbon dioxide laser technology. It is mainly used for non-metal carvings, such as leather and wood. The CO2 laser engraver is a general-purpose model with a small size and a high degree of integration.

Features:

- CO2 laser engraving machine can engrave any non-metallic material.

- It is processed in a non-contact manner and will not affect the material.

- The processing accuracy can be achieved by 0.02mm.

- The diameter of the beam and spot is small, less than 0.5mm. This saves material and is safe and hygienic.

- Not limited by the quantity of processing.

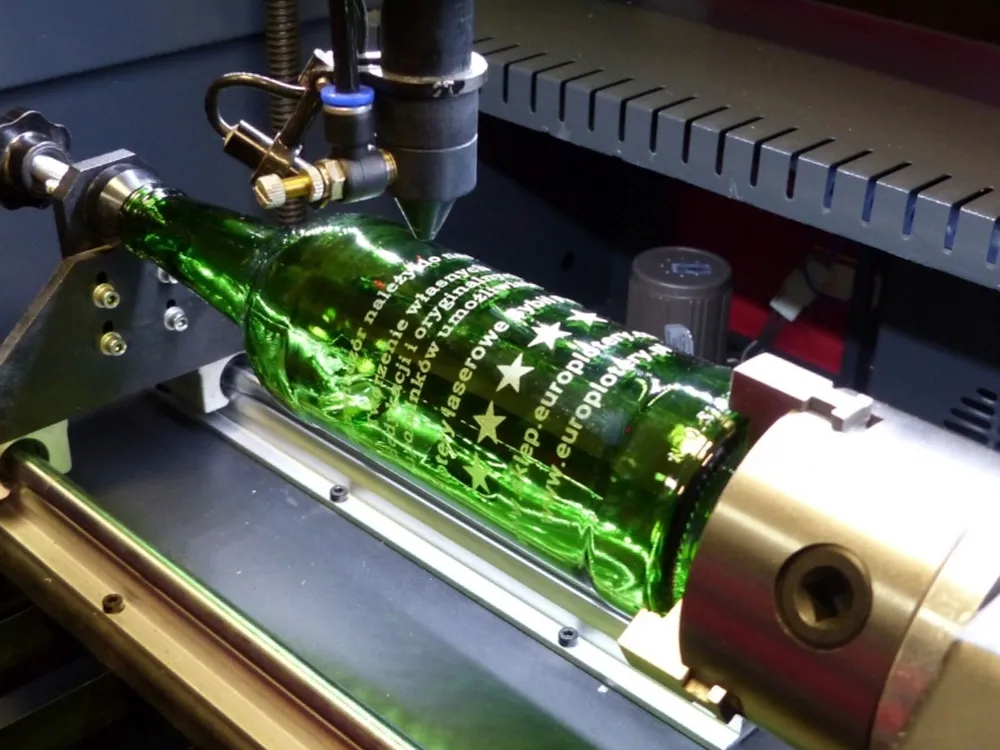

3D Laser Engraving Machine

Ordinary engraving laser machines can only work on flat surfaces. So 3D laser engraving machines became popular in the market. The 3D engraving laser machine can do arc engraving, embossing laser engraving, and large work area engraving.

Features:

- Fast speed, high precision, and good quality.

- Almost any material can be engraved.

- No need to open a mold. Directly use the computer to edit. Not limited by output.

- Any operator can quickly learn to run the operation process quickly.

- It can engrave various materials and surfaces of various shapes.

Five Factors of Choosing A Laser Engraver Machine

It is necessary to choose the correct engraving laser machine. It would be best to consider several factors when purchasing a laser engraver machine.

Format Size

The small-format engraving machine has 600mm×600mm and 600mm×900mm, and the feeding width is 700mm. Large format engraving machines are 1200mm×1200mm, 200mm×1500mm, 1500mm×2400mm, and 2400mm×3000mm. The feeding width of the engraving machine of these models is more than 1350mm. Engraving two-color plates is the most basic application of small-format engraving machines. And it is very receptive. The price of a smaller engraving machine is similar, but the board needs to be cut when engraving a two-color board. This is troublesome and causes unnecessary waste. The size of plexiglass and PVC boards on the market is 1300mm×2400mm. According to your needs and financial situation, choose the model and power of the engraving machine that suits you.

Spindle Motor

The spindle motor is an important component of the computer engraving machine. Its performance has a crucial impact on the performance of the whole machine. Machining spindles are generally divided into two categories: precision machining spindles and high-power cut-off spindles.

The fine processing spindle is characterized by low noise and high speed. It is suitable for processing delicate workpieces, such as seals, nameplates, badges, etc. This motor is usually a high-speed variable frequency motor with low power, generally below 250W. The disadvantage is that the ability to cut thick materials could be better.

The high-power cut-off spindle is mainly used for cutting off. It is characterized by high power and strong cutting ability.

Control and Speed

There are three types of control methods:

A. All computing work is completed by computer control. When the engraving machine works, the computer is in working condition. And other typesetting work cannot be performed. This may result in waste products due to the misoperation of the computer.

B. Using single-chip microcomputer control. This kind of controller can perform typesetting while the engraving machine is working. But it cannot shut down the computer. This will reduce waste products caused by the misoperation of computers.

C. Use the USB port to send data. The system has more than 32M memory capacity. You can leave the computer completely and do another typesetting as soon as you save the file. This method greatly improves the working efficiency of the engraving machine.

Guide

Large-format engraving machines must use widened imported square guide rails. Its load and precision retention capacity is more than 30 times that of circular guide rails. This can ensure the high quality and high speed of the engraving machine.

Precision

A small-format engraving machine engraving 4mm Chinese characters. Or a large-format engraving machine engraving 1.5mm small characters. They can be seen very clearly under a magnifying glass.

Laser Engraving Machine Precautions

- Pay attention to the fact that the autofocus rod must be tightened when using autofocus. Otherwise, the work surface will push against the laser head and make it out of the track.

- When the laser engraving machine is working, it is forbidden to open the machine cover (top cover and front cover). After opening, it will affect the laser emission, thus affecting the processing quality.

- The smoke exhaust and blowing equipment must be turned on when working. This prevents smoke and dust from contaminating the focusing and reflector lenses. Otherwise, it will affect the focus and reflection of the lens. Thus indirectly affecting the processing strength and precision.

- When processing wood and paper workpieces, close attention must be paid to processing speed and intensity. Avoid flames due to slow speed and high intensity. Flames will damage the focusing optics. The light ones will affect the processing strength and precision, and the heavy ones will damage the machine.

- Red light positioning must be first performed when processing irregular workpieces for initial users. This way, it can be determined whether the processing position is accurate. Otherwise, it is easy to produce waste products.

- When processing easily deformable materials such as veneer and cardboard, the deformation range should be adjusted so that the level difference is less than 1 mm. Avoid affecting the machining accuracy due to excessive focal length difference.

Laser Engraving Machine vs. Laser Marking Machine

Currently, the common laser equipment on the market includes laser engraving machines and laser marking machines. Many people think that these two machines are similar. So what is the difference between a laser engraving machine and a laser marking machine?

Working Principle

Laser marking machines use laser beams to make permanent marks on the surface of various materials. The function of marking is to expose the deep material through the evaporation of the surface material.

A laser engraving machine is a laser device that uses the thermal energy of a laser to engrave materials.

Different Lasers Are Used

Laser marking machine is mainly divided into CO2 laser marking machine, semiconductor laser marking machine, fiber laser marking machine, and YAG laser marking machine. Various lasers have different lifetimes. For example, the service life of a YAG solid-state laser is generally about 30,000 hours. Fiber laser marking machines have the longest service life, up to 100,000 hours.

Laser engraving machines can be divided into CO2 non-metal laser engraving machines and fiber metal engraving machines. The service life of a CO2 non-metal laser engraving machine is generally 2000-10000 hours. The fiber laser can be used continuously for more than 10w hours.

Processing Depth Varies

The laser marking machine only marks the material’s surface, and the depth is very shallow. The general depth is less than 0.5mm.

The depth of the laser engraving machine can be very deep, ranging from 0.1mm to 100mm, and can penetrate deep into the object.

Different Processing Speeds

The engraving speed of the laser engraving machine is generally the fastest engraving speed of 500mm/s.

Laser marking machines are generally three times faster than laser engraving machines.

Different Processing Technology

The laser engraving machine can be equipped with an electric lifting platform and rotating shaft. It can engrave regular or irregular objects such as cylinders, special shapes, and spheres.

Due to the optical path setting of the laser marking machine, the platform can adjust the focal length left and right. So it is mostly suitable for plane engraving.

Price

Different configurations, such as lasers and powers, will have different final prices. Generally speaking, laser engraving machines have deeper engraving depth and higher power. However, the printing depth of the laser marking machine is very shallow, and the laser power is low. The price of low power for non-metal laser engraving machines is much lower than for laser marking machines. But high-power laser engraving machines are also more expensive.

Final Thought

Now you have a basic understanding of laser engraving. Compared with traditional engraving methods, laser engraving does have many incomparable advantages. You can do laser engraving on any material, like leather, wood, or paper.

The laser engraving machine has excellent performance. But many friends need clarification in the face of various equipment on the market. Moreover, the high cost of laser engraving machines makes us more cautious in purchasing them. So how do we choose a laser engraving machine? It is very important for product quality, price, service, and many other aspects. The next article will focus on purchasing an engraving laser machine.