If you are searching for a laser cutting machine for metal, a fiber laser is the best machine for you. But if you want to mark organic materials like fabric and cardboard, a CO2 laser machine is the best option. The debate between these two technologies has been going on for some time. The CO2 laser machines have been on the market longer. It is only recently that fiber lasers became popular.

Many people believe CO2 laser is better because of its capabilities. While others think fiber laser is ideal because it brings many innovations into the equation. However, the actual answer to this debate depends on several factors. Each option works better depending on the application. The material you are marking, the level of precision required, and production volume are some factors determining the best to choose.

Overview of CO2 and Fiber Laser Cutting

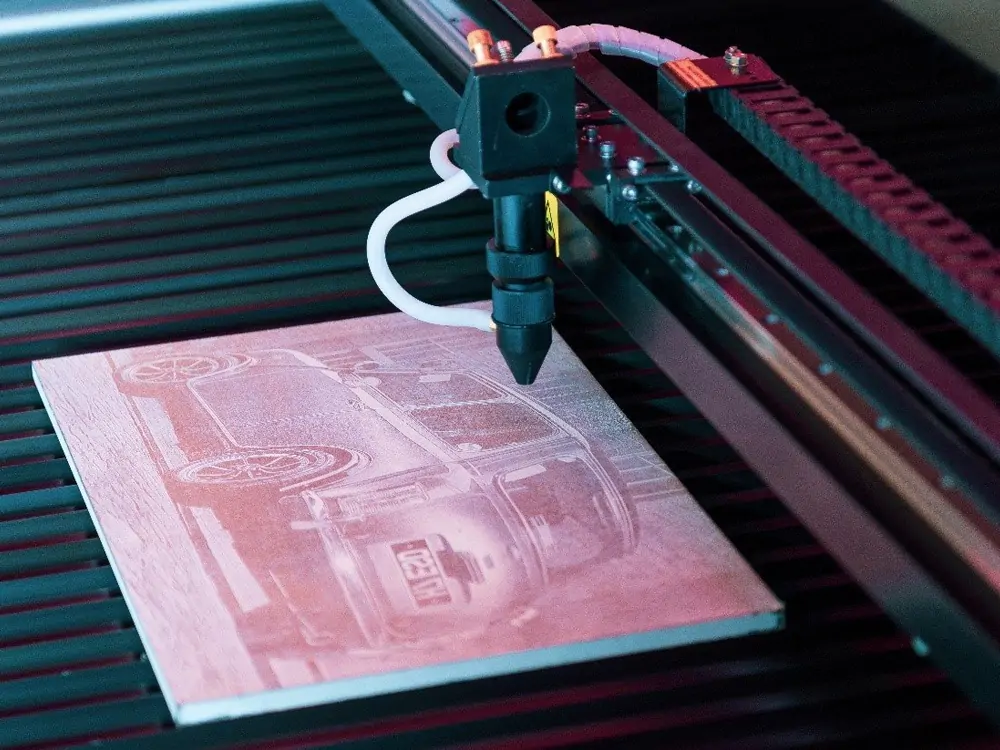

CO2 Laser Cutting Definition

The CO2 laser cutting technique is among the oldest technologies on the market. The technology was first introduced in 1972 and has undergone several development stages. Each CO2 laser cutter has a glass tube. Inside the glass tube is a mixture of gases, including carbon dioxide, hydrogen, nitrogen, and helium. When an electric current passes through this glass tube, it excites the atoms in the gas mixture to create a high-intensity light. This light travels through reflecting mirrors that guide it to the laser head.

The CO2 laser technology is dominantly used in the medical and manufacturing industries. The technique seems more cost-effective than fiber laser, especially in the initial cost. The small initial cost does not make CO2 laser cutters cheap. Compared to the fiber laser, CO2 laser cutters consume more electricity, which results in high operating costs.

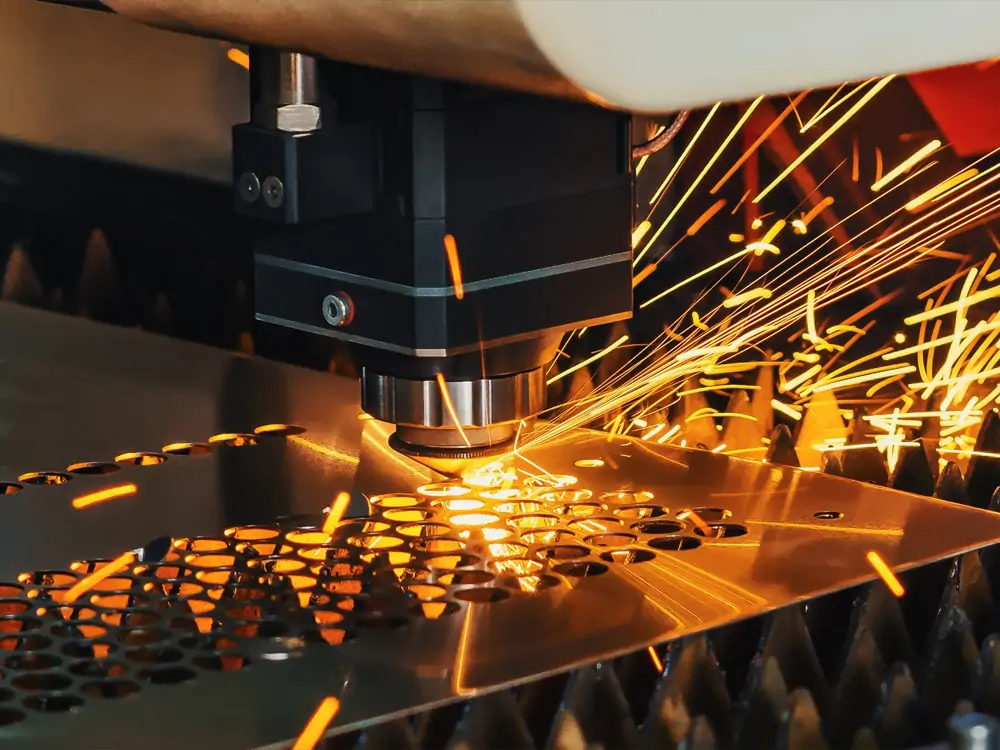

Fiber Laser Cutting Definition

Fiber laser cutting uses high-tech fiber optic materials to create an intense laser beam. It can cut through various materials. Fiber laser cutting works best in metal processing creating a precise and efficient cut.

The concept of fiber laser cutting is simple and robust. Unlike CO2 laser cutting, fiber laser does not encompass the light source. Fiber laser cutting focuses on focusing light to a single point using fiber optic components. Explaining the working mechanism of fiber laser cutting is simple. The fiber optic components receive the light and concentrate it into a single laser pointer. Fiber laser machines use CNC for precise and accurate cutting.

Additionally, the technique uses focal lenses to increase the accuracy of the fiber laser cutting system. Like CO2 laser, fiber laser cutting uses nitrogen or oxygen to ease the cutting process.

CO2 Laser and Fiber Laser Cutting Comparision

CO2 laser cutters have been in the market for five decades. Over the years, this laser cutting technique has undergone tremendous improvements. Fiber laser cutting has provided sheet metal processors with a viable alternative. Having both machines in your processing firm would be better if you are capable. If you have the budget, this comparison will help you decide which machine to buy.

Wavelengths

One of the primary different factors between a fiber laser and CO2 laser cutting is their wavelengths. A fiber laser emits a shorter wavelength. It is readily absorbed by the material, with minimal reflection of rays.

CO2 laser cutters emit higher wavelengths that are not readily absorbed by the material. There is a lot of energy loss in CO2 laser cutting due to the reflection of rays. For effective cutting, CO2 lasers consume more power than fiber laser cutters.

Fiber lasers can effectively make precise cuts because of their small spot size. A CO2 laser cannot achieve the precision of a fiber laser. Due to its large spot size, it is 90% larger than that of a fiber laser cutting machine.

Material Thickness

This is about the thickness each technique can cut. While these two laser cutting techniques can cut various materials, the thickness they achieve depends on the laser power.

Fiber laser cutting is new but has surpassed CO2 laser cutters to reach 15kW. Before finding a CO2 laser cutter with more than 6kW, you can travel the world. Fiber lasers can have higher power rates when laser cutting thick metal plates. Fiber lasers, so, have advantages over CO2 lasers.

Engraving Ability

Although CO2 and fiber laser cutters work the same, they achieve different results when engraving different materials. A CO2 laser cutter can engrave soft materials. Such as wood and plastic, but it cannot engrave on metallic materials. Even with a high-power CO2 laser, you still need to achieve pleasing results engraving on metal surfaces. The final product will have a rough finish.

However, a fiber laser cutting machine is perfect for sheet metal engraving. But it cannot engrave on soft non-metallic materials like wood.

Cut Material

If you want to laser cut a wide range of materials, a CO2 laser cutter is the perfect machine. This technique can cut non-metallic materials such as acrylic, plastics, wood, stone, leather, and fabrics. A CO2 laser cutter has a high wavelength unsuitable for metallic materials. Even so, if you combine a high-power laser with the correct parameters, a CO2 laser can process some metallic materials.

CO2 lasers are the most difficult to cut highly reflective metals. Such materials include, for example, aluminum, copper, and brass. But following specific techniques makes it possible to process aluminum with a CO2 laser.

Fiber laser’s short wavelength suits laser cutting, engraving, and etching on all metallic materials. Including brass and copper. Still, it will not cut or engrave non-metallic materials such as wood.

Although fiber laser can cut non-metallic materials, the final product is often too rough and unacceptable. The CO2 laser is the perfect technique for cutting non-metallic materials. While fiber is the best for metallic surfaces.

Processing Speed

This is another crucial differentiating factor between these two laser-cutting techniques. The speed at which one laser cutter processes a material depends on the thickness of the material. A fiber laser is faster than a CO2 laser cutting machine. A fiber laser cuts two to three times faster than a CO2 laser when processing a thin material of up to 5mm. Fiber laser cutting machines are available in higher power options. This improves the cutting speed irrespective of the material thickness.

The Finish

A CO2 laser cutting machine can produce a better surface finish than a fiber laser cutting machine. This difference becomes more visible as the cut depth increases. A fiber laser cutter produces fine parallel scratches when processing thick sheet metal. When engraving on metallic material, the tiny spot size in fiber laser cutters produces excellent markings on sheet metals.

Cost and Maintenance

When we talk about cost, it involves the initial and operational costs. These two are important factors when choosing between a CO2 and a fiber laser cutter. It is crucial to consider these two costs to determine whether the machine is right for you.

Initial Cost

Fiber laser cutters are quite costly compared to CO2 laser cutting machines. A fiber laser cutter machine costs three to four times that of a CO2 laser of the same power. While you would spend around $40,000 to purchase a high-end fiber laser cutter, you would spend approximately $15,000 to acquire a CO2 laser of the same caliber.

Although these are important costs, they cannot be the deciding factors when purchasing a laser cutting machine. Let us look at the operating cost of both.

Operating Cost

Mostly, laser cutting machines are cheaper to operate than to buy. But it is important to consider the operating cost. Because it increases with the initial cost to become the cost.

As seen earlier, a fiber laser is quite expensive to get. It is well-compensated by the minimal operating cost of the machine. A CO2 laser has a higher wavelength, requiring much energy to complete a project. Compared to a fiber laser, a CO2 laser consumes three times more electricity when cutting the same size material.

The operating cost of a CO2 laser further increases due to the constant need for auxiliary gas while processing a metallic material. This is unnecessary when working with a fiber laser. Especially when cutting thin metallic materials. This means a CO2 laser cutter is more expensive than a fiber laser.

Final Word

We could not possibly declare a winner in the debate between CO2 and fiber laser technologies. While fiber laser seems more effective, CO2 laser beats it when processing non-metallic materials. The choice you settle for primarily depends on the materials to want to cut.

Another factor to consider is whether you are buying a laser machine for cutting or engraving. You can use a CO2 laser to cut metallic and non-metallic materials. However, a fiber laser is best if your only business is engraving. For more information, please consult professional laser cutting machine manufacturers.