Laser welding technology has been widely used in modern manufacturing. It has become one of the key processes in various industries. Whether in automobile manufacturing, electronic equipment or medical equipment, laser welding machines are widely recognized for their high precision, high efficiency and reliability. However, for those considering purchasing a laser welding machine, it is crucial to understand the cost of laser welding machine.

In this article we will discuss welder laser machine price

factor. It can help you better understand the cost range of laser weld machine. The price of a laser welding machine is affected by many factors. Including device type, power, brand, features, additional equipment, etc. We’ll dig into these factors and give you a rough price guide. So that you can make an informed decision when purchasing laser welding equipment.

Whether you are new to laser welding technology or an industry professional, this article will provide valuable information. We’ll introduce the various laser welding machines and discuss their price ranges and features. You will learn where different classes and sizes of laser welding machines are suitable. And how to make an informed choice based on your needs and budget.

By reading this article, you will gain a comprehensive understanding about laser welding machine price. We want you to be able to make an informed buying decision for yourself or your business. Let’s explore laser welding machine prices and costs to provide a clear guide.

Factors Influencing Laser Welding Machine Costs

Technology And Capability

The price of a laser welding machine primarily depends on its technology and capabilities. Advanced machines with state-of-the-art features like high-powered lasers, precision controls, and multiple welding modes tend to be more expensive than their essential counterparts. These sophisticated features ultimately enhance welding precision, speed, and versatility. So they are ideal for complex applications.

Power Output And Laser Type

The power output and laser type play a pivotal role in determining the cost of a laser welding machine. High-power lasers for industrial applications deliver incredible welding speeds and deeper penetration depths. Hence its higher price. Furthermore, the type of laser used, such as fiber, CO2, or solid-state lasers, can influence the overall cost.

Work Area Size And Machine Configuration

The size of the work area needed for your requirements contributes to the cost of the laser welding machine. Machines with larger work areas tend to be more expensive. Because they can simultaneously accommodate more extensive parts or multiple smaller components. The machine’s overall configuration can also impact its price. This includes robotic arms, automated controls, and integrated safety features.

Laser Welding Machine Cost

The price range of laser weld machines varies depending on the brand, model, and features they offer. Typically, laser welding equipment fall within the price range of $5,000 to $10,000. However, there are some high-end models available that can go as high as $20,000 or more. To choose a suitable laser welder machine, it’s essential to consider not only the initial cost of the machine but also the cost of replacement parts and accessories.

Compared to traditional welding methods, laser welding proves to be a more efficient and effective technique. This allows for greater productivity in a shorter time. Consequently, even though the upfront cost of a laser weld machine may seem higher, the overall cost of ownership could be more economical. It’s also crucial to keep maintenance expenses in mind when deciding.

Different Laser Welding Machine Price

The laser welding machine cost varies from one machine to the other according to its specific function of use. Here, we will look at some welding laser machines, their price range, and some factors influencing their price.

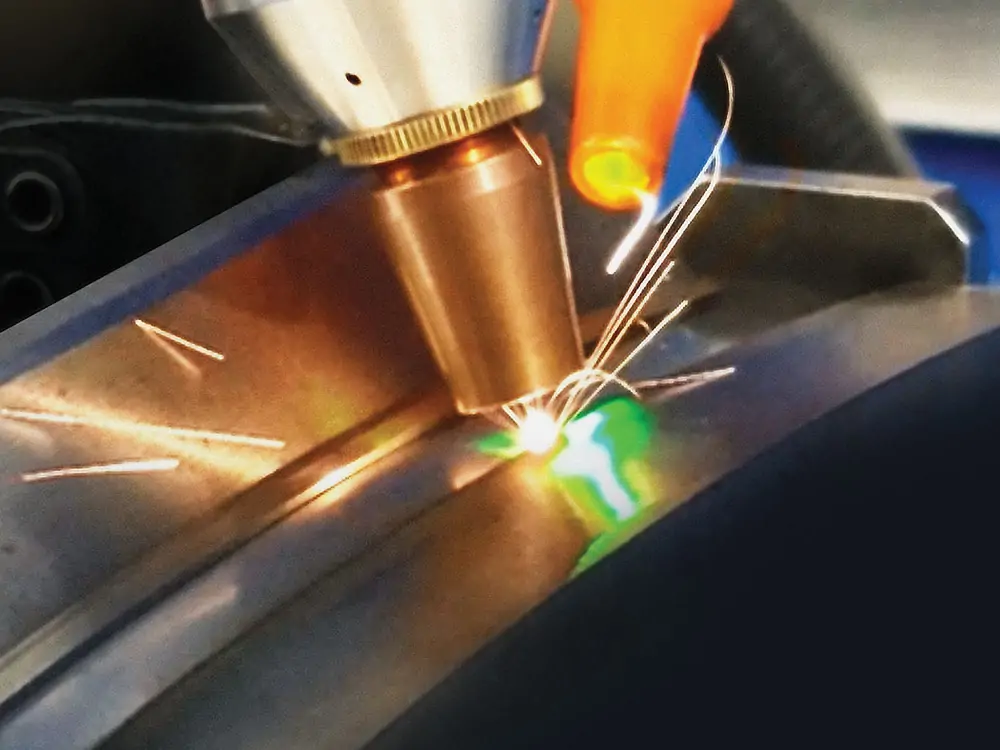

Fiber Laser Welding Machine

Fiber laser welding machine’s price can vary depending on several factors. One of the primary determinants is the power output of the machine. Machines with higher power output are generally more expensive. Because they can handle a broader range of materials and deliver faster welding speeds. Entry-level machines with lower power output can start at around $20,000. While industrial-grade machines with higher power output can range from $50,000 to over $100,000.

Another factor that influences the price is the size and build quality of the machine. Compact, portable machines are usually priced lower than larger industrial models for heavy-duty applications. The build quality and durability of the machine, along with its technology and features, also contribute to the pricing. Machines with advanced features like automatic controls, intelligent monitoring systems, and precise beam control may have a higher price tag.

The price also relies on the manufacturer’s brand and reputation. Well-established and reputable brands offer higher-quality machines with better customer support, which can reflect in the price.

It’s important to note that the initial cost of purchasing a fiber laser welding machine should not be the sole consideration. Other factors, such as maintenance costs, consumables, and training, should also be considered. Proper maintenance and regular servicing of these machines are crucial to ensure their longevity and optimal performance.

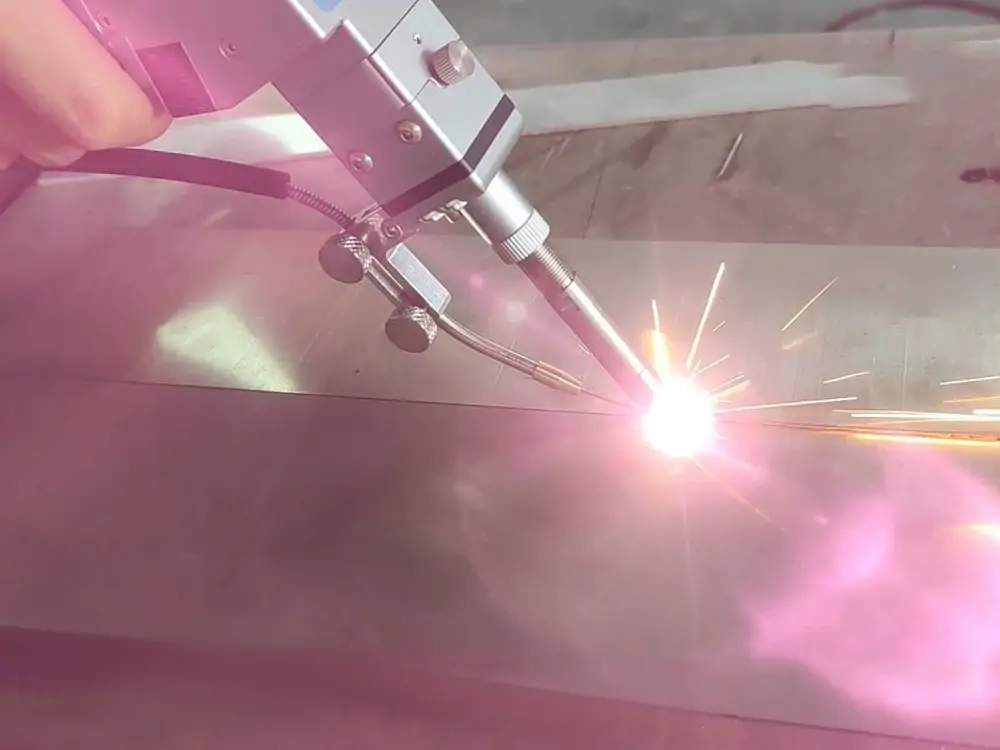

Handheld Laser Welding Machine

The handheld laser welding machine price can vary depending on several factors. Including the brand, specifications, power output, and other features. These machines can range from $5,000 to $50,000 on average. Some top-tier models exceed that range. It is important to note that these figures serve only as a general guide. The prices may differ depending on market fluctuations and individual seller policies.

Lower-priced handheld laser welding machines usually have fewer features and lower power outputs. So they are suitable for lighter use or small-scale operations. These budget-friendly options are ideal for startups or individuals seeking entry-level laser welding solutions. They offer an excellent opportunity to explore the capabilities of laser welding without breaking the bank.

As the price increases, so does additional features’ power output and quality. Mid-range handheld laser welding machines often offer a wider range of customization options, better user interfaces, and increased power outputs. So they suit more demanding applications. These mid-range machines balance affordability and functionality, making them popular choices among established businesses looking to upgrade their welding capabilities.

The high-end machines provide unparalleled precision and power. These machines boast advanced features. Such as automatic modes, inbuilt monitoring systems, and specialized welding modes for different materials. They can tackle even the most demanding and complex welding tasks with significantly higher power outputs. So they are crucial for heavy-duty industrial applications.

Despite the varying price ranges, handheld laser welding machines have become increasingly affordable in recent years. This is due to advancements in laser technology, manufacturing processes, and increased competition in the market. As a result, more manufacturers offer cost-effective solutions without compromising quality. A wider range of users will be able to use precision welding.

When considering the price of handheld laser welding machines, evaluating the long-term benefits is essential. These machines optimize welding operations and offer greater consistency and efficiency. So they improve productivity and reduce overall costs. Investing in a high-quality handheld laser welding machine can pay off in the long run. Because they simplify operations and ensure industry standards are met.

Small Laser Welding Machine

When purchasing a small laser welding machine, the price can vary based on factors. Such as a brand, features, power, and capability. Generally, the range for small laser welder machine prices starts from around $2,000 and can go up to $10,000 or more. This depends on your specific requirements.

This looks like a major investment to some. But it’s important to consider the long-term advantages of owning a small laser welding machine. The precision and accuracy offered by laser welding technology ensure immaculate welding joints. It has minimal distortion or damage to the surrounding area. This translates into higher efficiency and reduces the need for rework, ultimately saving time and resources.

Small laser welding machines occupy less space than large-scale industrial ones. It is suitable for businesses with limited workspaces. Their compact design allows for easy installation and mobility. Users can move the machine as needed, increasing flexibility and convenience.

These machines offer versatility in terms of material compatibility. Whether stainless steel, aluminum, copper, or even precious metals like gold and silver. A small laser weld machine can handle a wide range of materials. It is suitable for various applications like jewelry making, dental laboratories, electronics, and automotive industries.

It is crucial to note that the price of a small laser welding machine generally reflects its quality and performance. Therefore, choosing a reputable brand known for its reliability and customer support is essential. Purchasing from established manufacturers ensures a durable and long-lasting machine. And they can provide access to technical assistance and warranty coverage.

Conclusion

The cost of laser welding machine can vary greatly depending on various factors. Such as the type and power of the machine, additional features, brand reputation, and overall quality. Entry-level or smaller machines can be found between $10,000 to $20,000. High-powered or industrial-grade models can come with a $100,000 or more price tag. It is important to consider the specific needs and requirements of your welding projects and the long-term benefits, efficiency, and precision that a laser welding machine can offer. Investing in a suitable machine can result in significant cost savings, improved productivity, and higher-quality welds. This is a worthwhile investment for many businesses in various industries.