Laser marking seems simple until you dive deep into its technical breakdown. Different laser marking methods can be used depending on the material and your design. The standard methods are laser engraving and etching. You can use these two techniques in a wide range of industry applications.

Are you out shopping for a laser marking machine or laser marking services? Understanding the primary differences between laser engraving and etching will help you choose the best for your project.

Laser engraving and etching use similar technologies. But applying them to your marking projects brings out different results. On the one hand, laser engraving leaves a deeper cut by vaporizing the material. On the other hand, laser etching melts the material surface to create a design imprint.

Laser engraving creates durable markings. The technique is more invasive and less delicate. The satisfaction of each technique’s final product depends on the material and your needs.

This article will outline the main differences between these two laser marking techniques. You can use this information to determine the best approach for your project.

Laser Engraving Definition

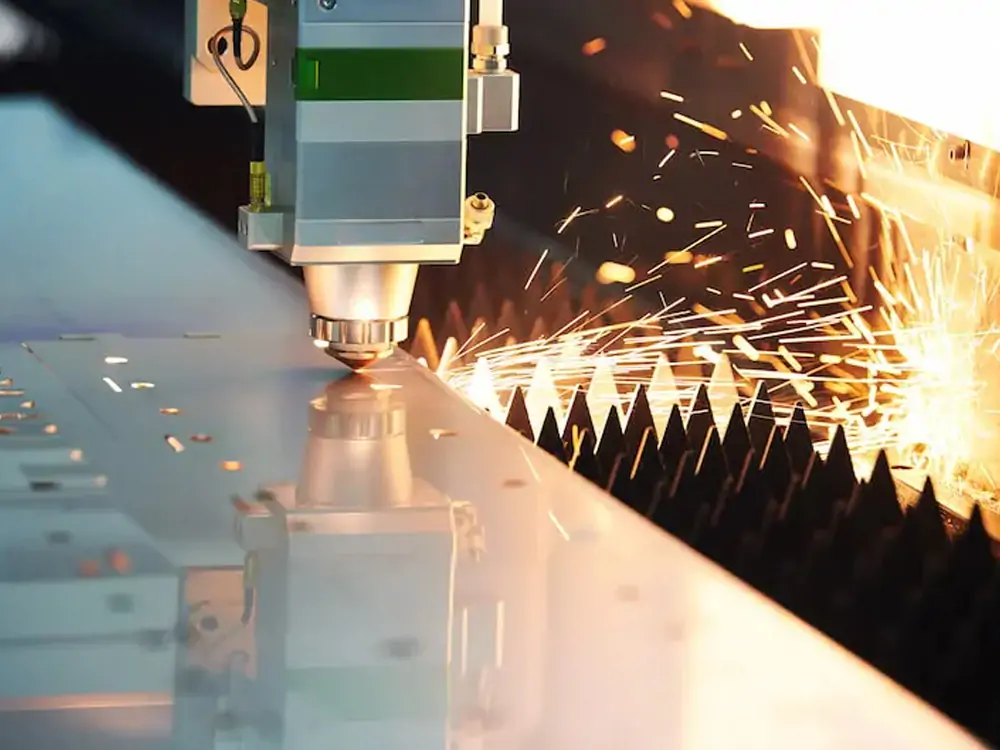

Engraving is a laser marking technique. The laser machine releases a massive amount of energy that acts like a chisel to the surface of your workpiece. The laser machine removes a chunk of the workpiece by vaporizing it away to incise a pattern.

Laser engraving is a common marking technique for products subject to wear and tear. You can use it to imprint durable logos, barcodes, or serial numbers on parts. It allows manufacturers to trace their products over a long time. Industries that appreciate the versatility of laser engraving include the automotive, aerospace, and medical industries.

You can use laser engraving mostly on metallic materials, especially stainless steel. Other metals include titanium and brass. Additionally, you can use the laser engraving technique on different materials. Such as wood, fiberglass, and paper.

Laser engraving uses fiber or carbon dioxide machines. It makes the technique perfect for metallic and organic materials.

Laser Etching Definition

Etching is a laser marking technique that uses a laser beam to emit a massive amount of energy to create markings on a surface. The laser beam heats and melts a surface area of the material, causing it to expand.

The expansion leaves a raised marking with a tactile feeling, which you can quickly see from a distance.

Like the laser engraving technique, you can use etching to create traceable markings such as QR codes, barcodes, and serial numbers. With laser etching, manufacturers can easily trace the production history of their products.

Like with laser engraving, you can use the laser etching technique on metallic materials. Such as various grades of aluminum, anodized aluminum, zinc, and stainless steel. You can also use laser etching on anodized, plated, and bare metallic surfaces.

The list of materials you can mark with laser etching is long and inexhaustible. You can also use laser etching on glass and polymers.

What Are The Primary Differences Between Laser Engraving and Laser Etching?

In laser marking, the machine you require depends mainly on the material you are marking rather than the process. If it is a metal surface, a fiber laser is the best machine. Metallic materials absorb fiber laser wavelengths more efficiently than other laser machines.

Therefore, whether etching or engraving, you need a fiber laser machine for metallic materials.

You will need a carbon dioxide laser machine when marking non-metallic materials such as wood or fiberglass. A CO2 machine is suitable for marking thin and flat materials such as fabrics, polymers, plastics, or cardboard. These types of machines are highly efficient and deliver precision.

Although laser engraving and etching are similar, they have huge differences that affect how you can use them.

Here are some of the primary differences.

Cut Indentation

Cut indentation is a vital deciding factor when choosing a laser marking technique. The cut depth determines the wear and abrasion resistance of the markings. A laser engraving process produces a cut indentation of up to 0.020 inches. The depth depends on the properties of your material, the power rating, and the energy density of your laser machine.

Highly reflective materials such as metal are more difficult to mark than less-reflective ones such as wood and cardboard. Additionally, different metallic materials have varied reflectivity properties that determine cut depths when etching or engraving.

Laser etching produces little or no cut indentation at all. Since this process does not perform cutting at all, the maximum cut depth created by a laser etching machine is 0.0001 inches. Unlike engraving, laser etching heats and raises the surface of your workpiece to make the markings.

Applications

Another distinguishing factor between these two laser marking techniques is their applications. Whether a hobbyist or an industrial manufacturer, you can use laser etching or engraving to create customized products for various purposes.

You can use these laser marking techniques to mark manufactured products for traceability purposes or create decorative patterns on custom products. You can use either for promotional item brandings such as pens, wine glasses, belts, and jewelry.

In industrial manufacturing, laser engraving and etching can be used in the automotive and aerospace industries, among other areas. These industries use laser etching and engraving to mark products or parts with their logos or brand names. They also use laser marking to keep parts with barcodes, serial numbers, or QR codes for traceability.

On the difference part, although you can use laser etching and engraving on similar applications for the same purposes, they differ in output. Laser engraved products are durable and versatile. The markings can last many years without fading or wearing out. Laser etched markings have an expected lifespan of at most ten years.

Which Industries Use Laser Engraving And Etching? How Do They Use Them?

Laser engraving and etching are applicable in the automotive, medical, and aerospace industries. The government requires manufacturers to make their products and parts traceable for safety purposes.

For instance, when a specific vehicle model develops a failure, manufacturers use the chassis numbers of all vehicles produced within that period to recall them for mass repair. Marked products are easy to track and determine the cause of their failures.

Laser etching and engraving are essential when you require permanent marking, even on the minor parts of a machine. For example, vehicle dashboard display screens have serial numbers in their motherboards. These numbers help technicians to determine the original replacement parts.

Manufacturers use laser engraving and etching to mark engine blocks, drive shafts, steering columns, transmission cases, and brake discs in the automotive. In aerospace, parts are marked with these laser techniques. Including electrical circuit boards, turbine blades, landing systems, gear components, and bolts. The medical industry uses laser etching and engraving to mark medical tubes, catheter connections, forceps, scalpels, body implants, and electrical circuit boards.

Production Volume and Cost

Another differentiating factor between laser engraving and etching is the production volume and cost of operation. Generally, laser engraving is more expensive than etching. The process requires a lot of energy and a more powerful technology than laser etching.

However, cost variation between the two laser marking techniques will vary depending on a few factors.

If your material is hard, the overall etching or engraving cost will be high. The character size and required cut indentation of your design will also determine the cost of the process. If a design is too complicated and requires deep cuts, the price will go high. Production volume also affects the cost of laser etching or engraving. Generally, the higher the volume, the more cost-effective the process.

Durability

Another difference between laser etching and engraving comes in the durability of the markings. Laser engraving creates more durable markings than laser etching. Although laser etching is quick and precise, it only melts the surface of your workpiece without any noticeable indentation.

Laser etched markings are not as wear and tear resistant as laser engraved markings. Mostly, a laser etched marking will last only between five and ten years. As such, you cannot use them on heavy-duty machines in harsh environments.

Laser engraving creates durable markings thanks to the cut indentation. They can last longer even when used in the harshest conditions. If you use a more powerful machine, the cut will go deeper, increasing the markings’ durability even more.

Conclusion/ Why Laser Engraving And Etching Are Important

Laser etching and engraving are important marking techniques. They ensure you can trace your products and parts and help you to adhere to government manufacturing regulations. Product traceability involves branding the product with a serial number or code that reflects its specifications.

Part traceability is a mandatory government requirement in several industries. For instance, medical parts require coding for safety and reliability reasons.

This article has discussed laser engraving and laser etching and explained their primary differences to help you determine what best suits your needs. Sincerely hope to be able to help you.